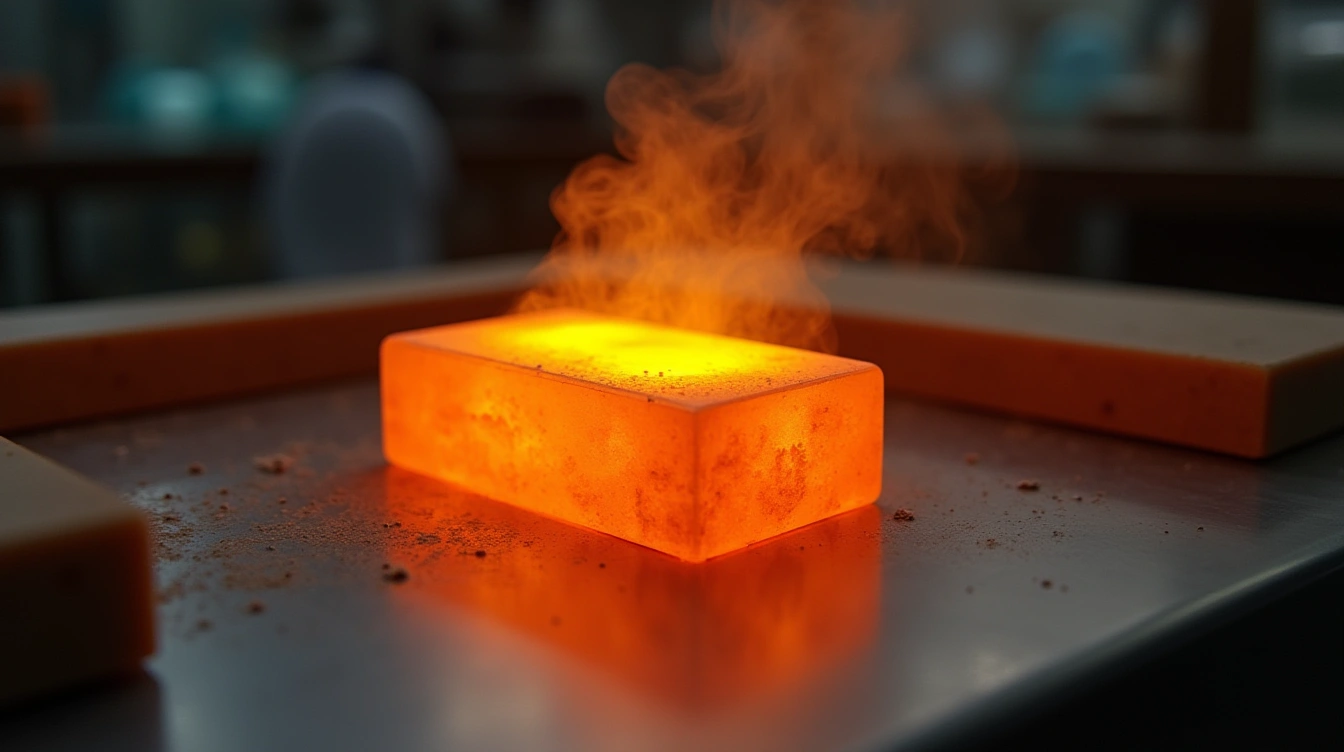

Custom refractory solutions transform high-temperature industrial processes by enhancing durability and efficiency. Tailored materials address specific challenges across steel, petrochemicals, and waste-to-energy sectors, ensuring thermal stability and mechanical strength. Choosing the right refractory means improved operational lifespan and cost savings, backed by expert design and advanced materials engineered for demanding environments. Unlock these benefits and optimise your thermal processes today.

Overview of High-Performance Refractory Solutions for Industry

Mxs-refractories specializes in delivering advanced solutions for high-temperature applications across industries like steel, cement, glass, petrochemical, and energy sectors. Refractory solutions are vital for protecting equipment and maintaining process efficiency under extreme heat.

In the same genre : Why Are UK Business Services Important for New Entrepreneurs?

Their products feature durability, thermal efficiency, and mechanical strength—essential for high-stakes environments. Saint-Gobain Performance Ceramics & Refractories is renowned for its resilient, custom-designed refractory offerings that withstand severe operating conditions. Their NORFLOW® castables are notable for ease of installation, low thermal conductivity, and shock resistance, making them popular for demanding environments.

Additionally, Trent Refractories provides bespoke solutions, emphasizing quality control and rapid delivery. Insertec excels with specialized refractory linings for foundries and furnaces, focusing on process optimization and safety. For more about tailored refractory solutions, visit the page: Mxs-refractories.

Also read : What role does remote work play in the evolution of UK business services?

Materials and Product Offerings in Refractory Industry

Refractory Material Selection Guide

High-alumina refractory materials, silica refractory components, and fireclay refractory bricks remain foundational choices in high-temperature materials for demanding industrial furnace linings. These materials deliver superior refractory heat containment strategies and contribute to better kiln lining techniques, especially in environments exposed to frequent thermal cycling and mechanical stress. For optimized refractory performance, choosing from advanced refractory cement products or thermal insulation technologies such as ceramic fiber insulation can boost efficiency and lower energy consumption. Specialized refractory castables, including dry mix refractory formulations, offer flexible refractory installation methods that adapt to industry standards and site requirements.

Durable and Specialized Refractory Products

Erosion-resistant refractory bricks and insulating firebricks address the need for abrasion-resistant linings and robust metallurgical heat shields. Castable refractory mixtures and monolithic linings are integral in sectors needing fireproof coating applications and enhanced thermal shock resistant materials. Custom heat containment systems—like customized refractory shapes—are suited for furnace relining processes, helping maintain refractory component durability while supporting energy-efficient heat barriers and high-grade insulating material. Reliable refractory installation safety and best practices ensure effective use across various refractory industry trends.

Industry-Specific Refractory Applications

In steel mill refractory solutions, blast furnace linings and EAF roofs benefit from refractory cement products and refractory kiln furniture supporting high-temperature stability and longevity. The cement plant heat barriers need silica refractory components and advanced industrial heat containment products for preheater and kiln linings. In the glass industry, furnace walls and temperature zones require glass industry lining materials that provide thermal insulation technologies and corrosion-resistant refractory coatings, enhancing durability and refractory lifecycle management.

Selection, Installation, and Maintenance Guidance

Selecting high-temperature materials begins with matching application demands—such as those in industrial furnace linings or kiln environments—to the correct refractory cement products. The right fit ensures both performance and long service life. When installing heat-resistant linings, using proven refractory installation methods reduces downtime and improves workplace safety. Step-by-step lining techniques, adherence to refractory installation safety, and specialized tools protect against hazards like heat exposure or dust.

Regular refractory maintenance best practices, including scheduled inspections and monitoring for wear, help identify potential failures early. If issues develop, targeted refractory repair services—like addressing cracks in erosion-resistant refractory bricks—can restore full functionality. Furnace relining processes use new or specialized refractory castables to reduce operational interruptions and optimize equipment longevity.

Consulting with experts—either through refractory design consulting or on-site technical support—enables tailored solutions for unique industrial challenges. Training personnel in proper kiln lining techniques and safety protocols supports consistent performance of all thermal insulation technologies, from ceramic fiber insulation in power plants to robust metallurgical heat shields in steel applications.